Involute Gear Hob Cutters (SPUR & HELICAL)

Involute Gear Hob Cutters

Gear Hobbing is the most commonly used methods Worldwide to cut Industrial and Automobiles gears which are done via Gear Hobbing machines.

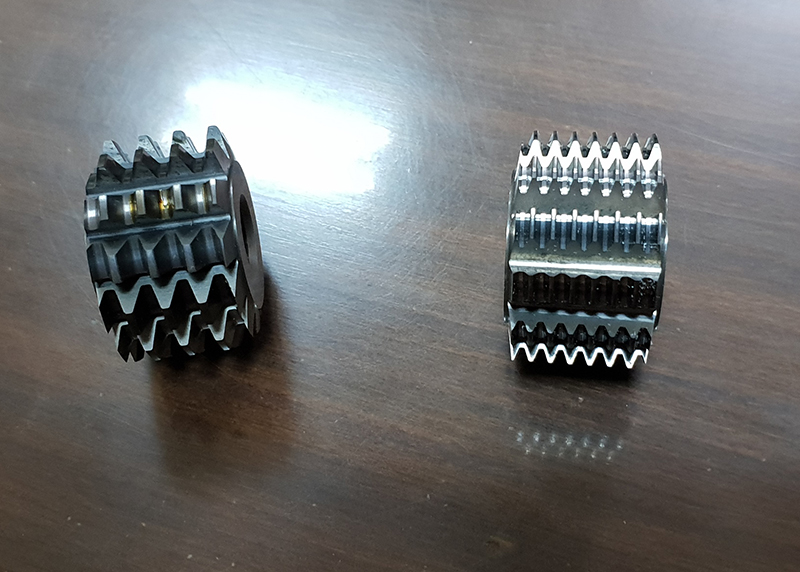

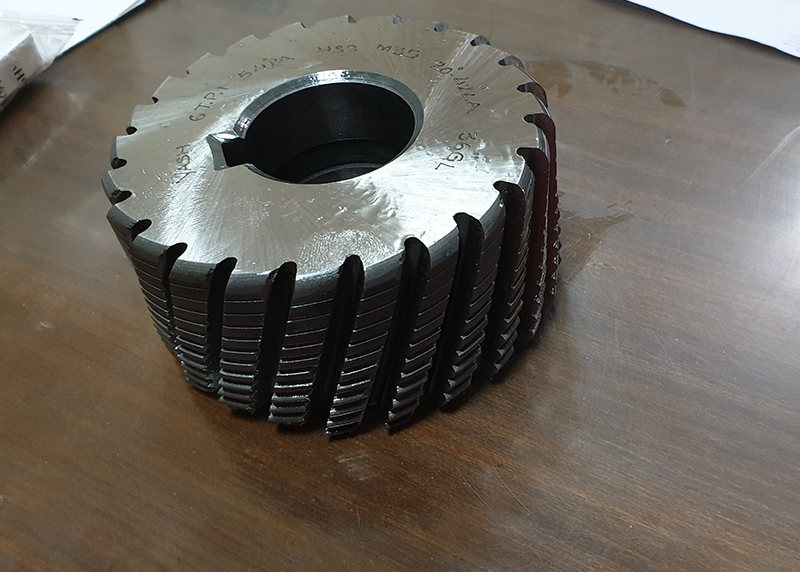

Yash Tools Produces wide range of Gear Hobbing cutters to cutall types of Spur, Straight, Helical, Involute Gear Profiles. . Most commonly used Gear hobs to cut any type of involute spur gear is done by Involute Gear Hob cutters. Our HSS made Gear hobs are specifically manufactured for generating profile of gears of maximum high accuracy for achieving finishing of gears as per DIN standards.

We have been exporting all type of gear Hobbing cutters worldwide since last 17 years. Our manufactured cutters are very high precision & high accuracy cutters upto Class AAA, AA, A as Per DIN 3968. We design Gear hobs according to the Component or gear data offered by client, standard or non-standard pitches. We use High Grain extensive & QualityHigh Speed Steel& powder Metallurgy Steeldirectly from All over world Steel mills to manufacture our supplied different types of Gear hobs.

Spur gears are involute in shape and for cutting these gears, solid involute gear hobs are designed specifically to the tooth profile of gear.

Raw material of gear hob cutters is suggested by us as per the hardness of gear (Rockwell / Brinell) to cut. Often times, there is huge number of gears of quantity which have to be cut by many AUTOMOBILE & INDUSTRIAL gear manufactures – we recommend them different types of raw material & surface PVD coatings 2-4 microns to have a smooth and better life of cutters.

Specifications of Involute Gear Hob Cutters / Basic Parameters –

Gear Pitch Range –

- 0.20Module to 45 Module

- 96 DP to 0.5 Diametric Pitch

Profile Forms:

- Non-Topping, With Topping, Semi-Topping, With Protuberance, Pre-shaving, Pre-grinding, Chamfer, full fillet etc.

Rotation of Gear hob:

- Right or Left Hand

Start:

- Single, 2 start or Multi Start (Upto 10 start)

Accuracy:

- AA, A, B Ground Finishing (as per DIN 3968 or equivalent AGMA, IS standard) &Machine Relieved “C” with all standard & non-standard profiles

PVD SURFACE COATING:

- 2-4 microns (OPTIONAL) Available in TiN, TiCN, ALTIN, ALCRONA Coatings

Material:

- HSS M-2, M35, PM ASP 30, ASP 52 or any special Required material

Quality - Complete Customer Satisfaction (CCS)

At Yash International, we believe in 3-sigma quality process

- 1 Maintaining World-class quality products & ensuring deliveries on-time

- 2 Providing most cost-effective pricing to our clients

- 3 Always ensuring complete customer satisfaction (CCS)

You will see technology at its best, be it in the components, the advanced production line or the well trained work force. We adhere to the exacting AGMA, DIN, BS, and JIS industry standards to maintain accuracies and preserve precise tolerances To maintain the best quality of the products we have adopted system of mandatory inspection and tests as well as periodic quality audits and system evaluations.

Certifications

We are a ISO 9001:2015 Certified company driven by Professional excellence, Technical competence and Total Quality Management system

MSME REGISTRATION (GOVT OF INDIA) CERTIFICATION\

REGISTERED MEMBER OF FEDERATION OF INDIAN EXPORTS ORGANIZATION (FIEO)

We, Commit ourselves for supplying products that would give complete satisfaction to customer. We will strive to achieve growth and leading position in the market by; supplying consistent quality products to our valued customers.

Get a Free Quote

Yash International

A-291/1,Okhla Industrial Area

Phase-I New Delhi -110020 (India)

A-291/1,Okhla Industrial Area

Phase-I New Delhi -110020 (India) Tel-+91-11-26812754,

Tel-+91-11-26812754,

+91-9811199390 sales@yashtools.com,

sales@yashtools.com,

yashinternational02@gmail.com